Judson_Supercharger

The Judson Supercharger

by Sam Buccilli

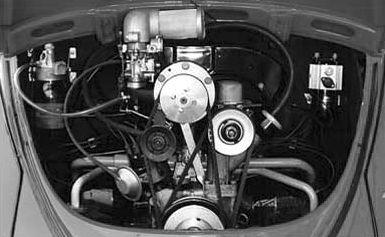

To understand how the Supercharger works we firstly have to understand the way an early flat 4 VW engine breathes. The power output of any internal combustion engine is limited by it's ability to take in air. In order to produce power the fuel must be combined with the correct weight of air to produce the energy needed to push the piston. An un-supercharged engine depends on getting the fuel/air mixture to the cylinder through suction created by the piston. Due to this it is uncommon that all of the cylinders are fully charged or completely filled with the explosive mixture and that all of the cylinders receive the same quantity or quality of mixture. As the speed is increased, the time for each suction stroke is decreased and the quick short sucking of the piston at high engine speed is not able to fill all of the cylinders completely. The power curve on a supercharged engine continues to rise as the speed increases past the point where on an unsupercharged engine the torque starts to fall off.

The designers at Wolfsburg deliberately created an engine with restricted breathing. This limited the power output and thus created an engine that was renowned for its reliability as it was not subject to excess stresses over long periods. Torque and speed determine the horsepower produced by an engine. Therefore there are two ways of increasing the horsepower of an engine - either by increasing the torque or the speed (rpm). Engine modification in the form of multiple carburettors, special manifolding, high compression heads, high lift cam etc. generates increased horsepower by increasing engine speed. The amount of stress on engine components increases with the square of the speed so a crankshaft turning at 6,000 rpm has four times the load of a crankshaft turning at 3,000rpm. Supercharging an engine only increases the firing pressures whereas it is the inertial stresses (speed) that is the principal cause of engine failure.

A supercharger works not by suction but by forcing the air into the cylinders under pressure increasing the horsepower developed by an engine through increasing the torque. A supercharger is simply a blower or compressor usually mounted between the carburettor and the intake manifold. When the valve opens the full charge of air/fuel mixture is waiting to enter into the cylinder and all of the cylinders are completely filled with a uniform charge of fuel/air mixture, the engine therefore does not loose it's compression as speed increases. This overcomes the restricted breathing of the normally aspirated engine and makes the engine run much more efficiently.

Judson's figures stated that "Average fuel consumption is increased by approximately 5%" This 5% is a significant figure with fuel prices however I'm sure you will agree that the increase in performance more than makes up for the extra expenditure. However despite the small increase in fuel used, better fuel economy is achieved overall by using a supercharger than without as the fuel that is burnt is used to power the engine more efficiently and provide more horsepower.

The amount of horsepower produced by an engine will increase in direct proportion to the amount of fuel/air forced into the cylinder - a conservative supercharged pressure of 5 to 6psi (lbs per sq in) will increase the horsepower developed by the engine by 40 to 50%. The vacuum used by the unsupercharged engine to suck the mixture into the piston also sucks oil past the piston into the combustion chamber. On a supercharged engine this vacuum is not present so as a result the oil is not drawn in and burnt also reducing engine oil consumption.

Judson's figures stated that "Average fuel consumption is increased by approximately 5%" This 5% is a significant figure with fuel prices however I'm sure you will agree that the increase in performance more than makes up for the extra expenditure. However despite the small increase in fuel used, better fuel economy is achieved overall by using a supercharger than without as the fuel that is burnt is used to power the engine more efficiently and provide more horsepower.

The amount of horsepower produced by an engine will increase in direct proportion to the amount of fuel/air forced into the cylinder - a conservative supercharged pressure of 5 to 6psi (lbs per sq in) will increase the horsepower developed by the engine by 40 to 50%. The vacuum used by the unsupercharged engine to suck the mixture into the piston also sucks oil past the piston into the combustion chamber. On a supercharged engine this vacuum is not present so as a result the oil is not drawn in and burnt also reducing engine oil consumption.

The Judson is a positive displacement rotary vane unit with 4 vanes - this means that it compresses the mixture from the carburettor by way of a series of sliding vanes located on an eccentric hub. As the hub rotates the vanes are thrown outwards and seal against the wall of the supercharger. This pressurises the mixture and pushes it into the intake manifold. This supercharger is recognised scientifically as the most efficient and best suited to automotive applications. The temperature of the mixture is not increased on the vane type supercharger due to a change in volume as the mixture leaves the supercharger and enters the intake manifold of the engine. This type of supercharger has no cams or gears to wear and cause a loss in efficiency and it is absolutely silent in operation. It operates at engine speed and can perform well throughout the entire speed range of the engine.

Lubrication is most important in a Judson set up and a lubricator bottle is required. This supplies a constant supply of special oil to lubricate the phenol impregnated linen vanes of the supercharger. The oil is burnt with the fuel mixture in the combustion chambers and it also acts as an upper cylinder lubricator. The non metallic linen vanes moving on a film of oil are used to eliminate metal to metal contact and thus reduce friction within the supercharger unit, this reduces the operating temperature. Judson specified that their supercharger would use one quart of oil in approximately 1,000 miles.

With the Judson supercharger being an automatic device the engine is supercharged only when the driver requires additional power. This is determined by the load placed on the throttle. The supercharger is not used at idle, in town traffic or in normal motorway cruising. When the throttle is suddenly depressed by opening the accelerator the engine is immediately supercharged. Although the engine is not continuously supercharged the supercharger is always in operation providing increased volumetric efficiency even at idle - allowing for a much smoother and more efficient running engine.

So in improving the breathing ability of the engine are we sacrificing the long-term reliability? The advantage of the sliding vane Judson is that the vanes are closed and the unit providing boost only when the throttle is opened. At cruising speed the manifold pressure is near normal despite the fact that the vanes are still rotating, this reduces the wear, fuel consumption and most importantly the heat produced. A supercharged engine suffers less cylinder wear than in an unsupercharged because a wet mixture is never placed on the cylinder walls due to the increased atomisation of the fuel under pressure.

Lubrication is most important in a Judson set up and a lubricator bottle is required. This supplies a constant supply of special oil to lubricate the phenol impregnated linen vanes of the supercharger. The oil is burnt with the fuel mixture in the combustion chambers and it also acts as an upper cylinder lubricator. The non metallic linen vanes moving on a film of oil are used to eliminate metal to metal contact and thus reduce friction within the supercharger unit, this reduces the operating temperature. Judson specified that their supercharger would use one quart of oil in approximately 1,000 miles.

With the Judson supercharger being an automatic device the engine is supercharged only when the driver requires additional power. This is determined by the load placed on the throttle. The supercharger is not used at idle, in town traffic or in normal motorway cruising. When the throttle is suddenly depressed by opening the accelerator the engine is immediately supercharged. Although the engine is not continuously supercharged the supercharger is always in operation providing increased volumetric efficiency even at idle - allowing for a much smoother and more efficient running engine.

So in improving the breathing ability of the engine are we sacrificing the long-term reliability? The advantage of the sliding vane Judson is that the vanes are closed and the unit providing boost only when the throttle is opened. At cruising speed the manifold pressure is near normal despite the fact that the vanes are still rotating, this reduces the wear, fuel consumption and most importantly the heat produced. A supercharged engine suffers less cylinder wear than in an unsupercharged because a wet mixture is never placed on the cylinder walls due to the increased atomisation of the fuel under pressure.

In addition to providing an increase in horsepower and better performance a supercharger can also produce a smoother running engine eliminating loss of power at high altitudes and high temperature. Also due to the increased atomisation of the fuel the car is easier to start particularly in the cold.

Adding a Judson to an old over tired engine in poor condition would be detrimental to performance. Judson always advised that the stock engine must be in good condition, well run in and properly tuned. Judson also insisted that their superchargers should only be used on the engines that they were designed for and not be adapted to fit a different vehicle. Included in a Judson kit was a carburettor jet to furnish the correct mixture required and notes regarding exact ignition settings alongside the relevant pulley belts and brackets required for installation.

To Purchase a Judson today would cost upwards of £500 for a second hand kit to between £1000-£1500 for a complete boxed item. If you are looking to buy a fully restored item from a Judson restoration expert then you will expect to pay between $1500 - $1800 dollars for a VW kit. If buying a fully restored kit is too rich for your blood then what do you need to know to purchase a kit second hand. Firstly if buying over the internet you need good quality photos of all of the components and a full listing of all items included in the sale to ensure that there are no components missing or replaced with non genuine parts. One of the major considerations when purchasing a supercharger is the internal condition of the body. The profile of the four slots that house the vanes in the rotor is most important - they should be parallel when viewed from the ends with a minimum of flaring due to age related wear. If the vanes are damaged you will be looking around $80 to replace and the rotor itself would be around $400. For a VW Beetle the supercharger kit included the following items : Supercharger body, double crankshaft pulley, alloy air cleaner assembly, generator flange, supercharger support, 2 drive belts, oiler including 2 support brackets 4 screws and oil line, 3 main gaskets for the blower to inlet manifold, throttle rod, carburettor control arm, 2 carburettor studs, 2 supercharger studs, no. 140 carburettor jet, fuel pump spring, choke wire, windshield decal and instruction leaflet.

So there you have it the Judson supercharger. This is a fantastic period accessory which will give you that added horsepower often needed when driving your vintage VW on the modern motorways. This accessory is becoming very popular again on the vintage show circuit but bear in mind that like your 30bhp engine you will need to give it love and attention. The Judson supercharger is a vintage piece in itself and you can not walk into your local VW spares business and pick up parts off of the shelf. For further information on installation and running a Judson supercharger check out the Judson register on the Internet at http://vwjudsonregister.tripod.com/. The old website is now closed as of late 2015, the link supplied here will lead you to the new sources of information on the Judson supercharger.

Back

Adding a Judson to an old over tired engine in poor condition would be detrimental to performance. Judson always advised that the stock engine must be in good condition, well run in and properly tuned. Judson also insisted that their superchargers should only be used on the engines that they were designed for and not be adapted to fit a different vehicle. Included in a Judson kit was a carburettor jet to furnish the correct mixture required and notes regarding exact ignition settings alongside the relevant pulley belts and brackets required for installation.

To Purchase a Judson today would cost upwards of £500 for a second hand kit to between £1000-£1500 for a complete boxed item. If you are looking to buy a fully restored item from a Judson restoration expert then you will expect to pay between $1500 - $1800 dollars for a VW kit. If buying a fully restored kit is too rich for your blood then what do you need to know to purchase a kit second hand. Firstly if buying over the internet you need good quality photos of all of the components and a full listing of all items included in the sale to ensure that there are no components missing or replaced with non genuine parts. One of the major considerations when purchasing a supercharger is the internal condition of the body. The profile of the four slots that house the vanes in the rotor is most important - they should be parallel when viewed from the ends with a minimum of flaring due to age related wear. If the vanes are damaged you will be looking around $80 to replace and the rotor itself would be around $400. For a VW Beetle the supercharger kit included the following items : Supercharger body, double crankshaft pulley, alloy air cleaner assembly, generator flange, supercharger support, 2 drive belts, oiler including 2 support brackets 4 screws and oil line, 3 main gaskets for the blower to inlet manifold, throttle rod, carburettor control arm, 2 carburettor studs, 2 supercharger studs, no. 140 carburettor jet, fuel pump spring, choke wire, windshield decal and instruction leaflet.

So there you have it the Judson supercharger. This is a fantastic period accessory which will give you that added horsepower often needed when driving your vintage VW on the modern motorways. This accessory is becoming very popular again on the vintage show circuit but bear in mind that like your 30bhp engine you will need to give it love and attention. The Judson supercharger is a vintage piece in itself and you can not walk into your local VW spares business and pick up parts off of the shelf. For further information on installation and running a Judson supercharger check out the Judson register on the Internet at http://vwjudsonregister.tripod.com/. The old website is now closed as of late 2015, the link supplied here will lead you to the new sources of information on the Judson supercharger.